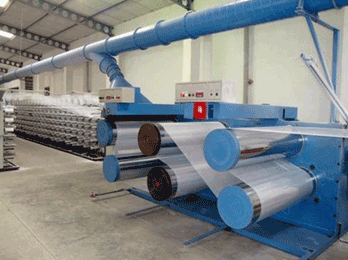

The extrusion process constitutes the initial stage of production, wherein a homogenous blend of virgin polypropylene (PP) granules is compounded with controlled quantities of calcium carbonate filler, ultraviolet (UV) stabilizers, and optional color masterbatch. The mixture is thermally plasticized and extruded through a flat die to produce tapes with tightly controlled width and thickness specifications. These extruded tapes are subsequently quenched, slit, and oriented to enhance molecular alignment, thereby defining the tensile strength, elongation, and overall mechanical performance of the material. The finished tapes are then wound under controlled tension onto industrial bobbins for downstream weaving operations.

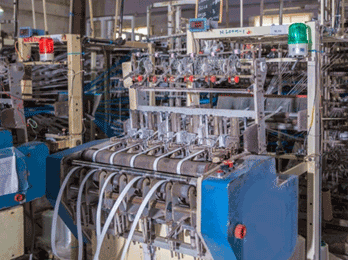

The oriented polypropylene tapes produced during extrusion are mounted onto circular, where they are interlaced in warp and weft configurations to form a woven polypropylene fabric. Loom parameters such as tape density, weave pattern, and tension control are carefully regulated to achieve the required fabric strength, dimensional stability, and load-bearing capacity for bulk bag applications. The resulting fabric exhibits high tensile and tear resistance, making it suitable for transporting a wide range of industrial and food-grade materials. In addition to forming the main body panels of bulk bags, the woven PP fabric is also utilized in the manufacture of filling spouts, discharge spouts, and other functional components.

During the webbing stage, high-denier polypropylene tapes are processed into woven webbing specifically designed for load-bearing applications. These tapes are interlaced on narrow-fabric looms to produce webbing with enhanced tensile strength, abrasion resistance, and dimensional stability. The finished webbing is then cut into strips of precise lengths, determined by the bag design, safe working load (SWL), and handling requirements. These strips serve as the lifting loops, or handles, of the bulk bags. In most standard bulk bag configurations, the webbing is integrated along the vertical seams on all four sides of the bag, with lifting loops extending above each corner to ensure balanced load distribution during lifting and transport.

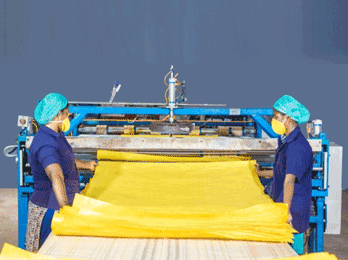

In the cutting stage, rolls of woven polypropylene fabric are fed into automated cutting and slicing equipment, where they are trimmed into panels with predefined dimensions and geometries. Cutting parameters are programmed according to the specific bag configuration, determining whether side panels, base panels, or tubular sections are being produced. Computer-controlled length measurement and cutting systems ensure high dimensional accuracy and repeatability for each component. At this stage, fabric is prepared to accommodate various bulk bag designs, including square, tubular, and vertically rectangular constructions, with all cuts executed to meet precise production and assembly requirements.

Once the pieces of the polypropylene fabric have been cut into shape, they are fed into a printing machine. Here, impressions are made on the fabric. If a company has a brand name or logo that they want to be applied to a line of bags, the printing occurs at this stage. Depending on the brand in question, an assortment of colors may be implemented. For the best possible impressions, a heavy-duty printer is necessary for this process which SDR Polymers has.

At this stage, the various pieces that comprise the bulk bag — including both the square and rectangular pieces of polypropylene fabric, as well as the heavier lifting-loop strips — are put together with an industrial sewing machine. Bulk bags are sewn together in mass quantities by a team of trained hands under the watchful eye of technical supervisors. Each seam must be straight, tight and secure, with no creases or bends along any of the sides or bottom ends.

Once a line of bulk bags has been sewn together, each bag is inspected by quality control inspectors. The purpose is to ensure each bag meets the required standards of strength and durability for a product line of bulk bags. If any bags are found to be insufficiently sewn, they are removed.

Once a line of bulk bags has been sewn together, each bag is inspected by quality control inspectors. The purpose is to ensure each bag meets the required standards of strength and durability for a product line of bulk bags. If any bags are found to be insufficiently sewn, they are removed.